Add to Cart

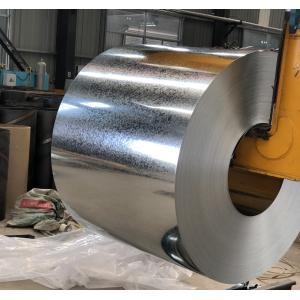

S250GD Hot Dipped Galvanized Steel Coil Zinc Coated For Commercial use roof panel with ISO Approval

Hot Dipped Galvanized Steel Sheet in Coil (GI) is produced by passing the Full Hard sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc’s characteristics. Usually, hot-dipped galvanized steel sheet and galvanized steel coil process and specifications are basically the same.

Hot-dip galvanizing is the process of applying a protective zinc coating to a steel sheet or iron sheet, to prevent rusting.

Excellent anti-corrosion, paintability, and processability due to the self-sacrificing characteristic of zinc.

Available to select and produce the desired amount of zinc gilded and in particular enables thick zinc layers(maximum 120g/m2).

| Product Name | Manufacturer Hot Rolled Galvanized Steel Coil |

| Thickness | 3mm-200mm |

| Width | 610mm-1500mm or according to customer's special request |

| Tolerance | Thickness: ±0.03mm Length:±50mm Width: ±50mm |

| Zinc Coating | 30g-275g/m2 |

| Material grade | SGCC ,DX51D+Z, CGCC/SGCH/SPCC/SPCD/SPCE/DC01 |

| Surface treatment | Chromated unoiled,galvanized |

| Standard | ASTM,JIS, EN, BS, DIN |

| Certificate | ISO9001,BV |

| Package | First with plastic package, then use waterproof paper, finally packed in iron sheet or according to customer's special request |

| Application range | Widely used for roofs, explosion-proof steel, electrically controlled cabinet sand industrial freezers in the residential and industrial buildings |

1. Prepainted Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Prepainted Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Prepainted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.